Inventory is one of the biggest challenges modern multi-channel sellers face. Nearly 43% of businessesstill rely on manual or outdated inventory methods, leaving them vulnerable to stockouts, overselling, and poor fulfillment decisions. Multichannel sellers collectively lose over $1 trillion each year due to inventory distortion caused by poor visibility and inaccurate stock data.

As customers shop across ecommerce sites, marketplaces, and physical locations, expectations for accuracy are higher than ever. Multichannel Inventory Management helps sellers meet those expectations by syncing stock across all channels in real time, reducing errors, protecting revenue, and enabling confident growth.

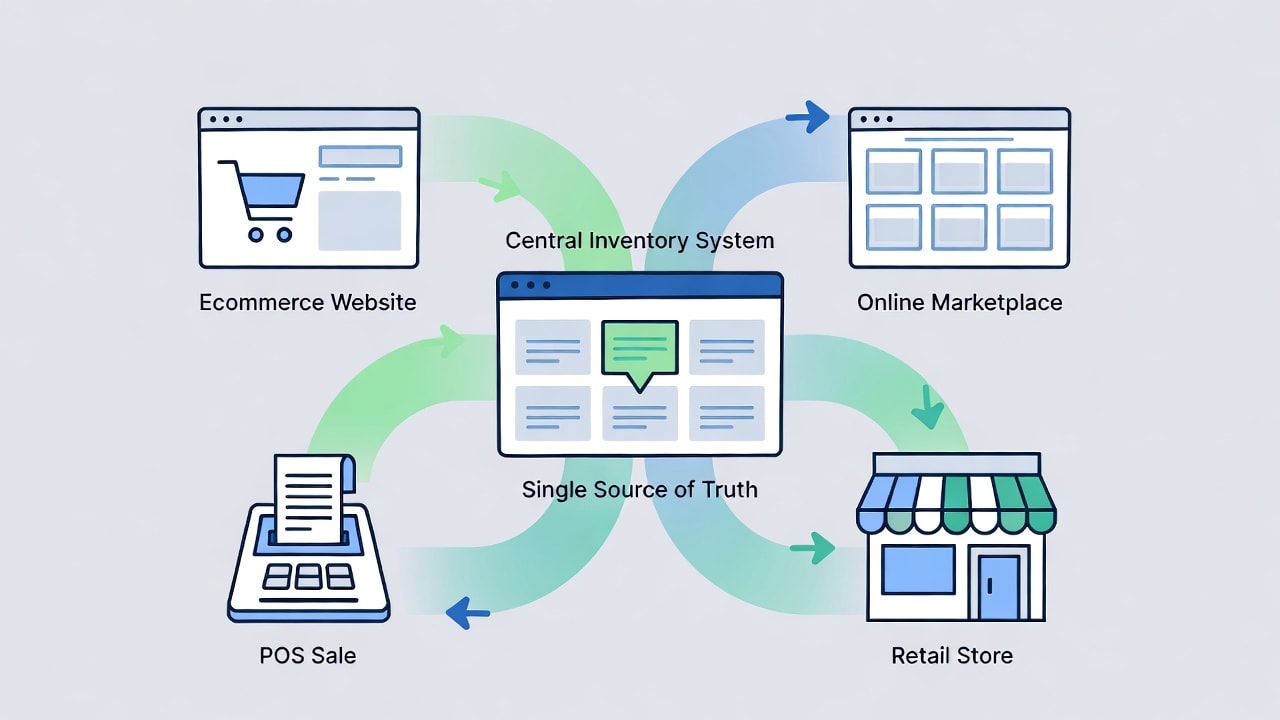

What Is Multichannel Inventory Management?

Multichannel inventory management is the process of tracking, managing, and fulfilling inventory across all your sales channels through a single, centralized system. Think of it as a single “source of truth” for your stock: when a sale occurs on one channel, inventory updates automatically across all other platforms without manual work.

For example, if one hoodie sells on Amazon, the stock count instantly updates on Shopify, Etsy, and your physical stores. Overselling is prevented, customers only see what’s truly in stock, and fulfillment stays accurate.

Modern multi-channel sellers often sell across multiple channels, such as:

- Physical retail stores

- E-commerce websites

- Online marketplaces (Amazon, eBay, Etsy)

Without multi-channel inventory management, growth quickly leads to stock mismatches, missed orders, and frustrated customers. A centralized system provides real-time visibility, keeps inventory aligned across all channels, and streamlines operations.

Benefits of Inventory Automation For Modern Multi-Channel Sellers

As sales channels multiply, inventory complexity grows. Without automation, accuracy breaks down and revenue leaks through overselling and stockouts. Automated inventory syncing creates a single, real-time view of stock that supports confident scaling.

1. Prevent Revenue Loss Before It Happens:

Automated inventory syncing ensures products are only sold when stock is actually available. Without it, overselling leads to canceled orders, refunds, and missed revenue that often isn’t discovered until after customers are affected.

By keeping inventory accurate across all channels in real-time, automation reduces stockouts, excess inventory, and the hidden revenue loss caused by poor visibility.

2. Build and Protect Customer Trust:

Customers expect consistent availability no matter where they shop. When one channel shows an item in stock, and another doesn’t, confidence erodes. Even if the issue is purely technical.

Inventory automation keeps stock levels aligned everywhere, creating a reliable buying experience that builds trust and encourages repeat purchases.

3. Eliminate Manual Inventory Work:

Manual updates might work early on, but they break down quickly as SKUs, orders, and sales channels increase. Teams spend more time updating spreadsheets and correcting errors than focusing on growth.

Automation removes repetitive inventory tasks, allowing teams to manage by exception instead of constantly chasing inaccuracies.

4. Reduce Operational Disruptions:

Overselling creates downstream problems like support tickets, fulfillment delays, negative reviews, and frustrated customers. Each issue adds cost and operational strain.

With automated inventory updates, stock issues are prevented before orders are placed. Keeping fulfillment smooth and operations predictable.

5. Enable Faster, Smarter Decisions:

Real-time inventory automation gives teams a clear, accurate view of stock across all channels and locations. This visibility allows for better allocation, faster response to demand changes, and more confident decision-making.

When inventory is automated, it stops being a risk factor and becomes a foundation for sustainable, multi-channel growth.

Common Multichannel Inventory Challenges in Multi-Channel Selling

Expanding beyond a single channel opens huge growth opportunities. But it also exposes brands to hidden pitfalls that silently drain revenue and hurt customer trust. Here’s what most e-commerce teams face when their inventory isn’t fully synced:

1. Overselling and Stockouts:

Selling the same SKU twice is more than a minor hiccup. It triggers cancellations, refunds, and angry reviews that damage your marketplace rankings. Nearly 70% of online shoppers switch to competitors if an item is out of stock. Even small gaps can cost you sales and customer loyalty.

2. Fragmented Visibility:

When inventory lives in spreadsheets or disconnected tools, nobody really knows what’s available. Teams make decisions with incomplete data, leading to costly reactive workflows and wasted time. Globally, inventory distortion from overstocks and stockouts totals $1.77 trillion annually.

3. Deadstock and Overstock:

Excess inventory ties up cash that could fuel growth. Many brands waste 20–40% of working capital sitting in unsold products. Overstock not only hurts cash flow but also increases storage and handling costs, reducing overall profitability.

4. Forecasting Failures:

Without real-time, synced inventory data, forecasting becomes guesswork. Too much stock means waste. Too little means missed sales. In the U.S. grocery industry alone, stockouts cost approximately $15–20 billion annually, accounting for roughly 3% of total sales.

5. Replenishment Delays:

Disjointed updates slow restocking. Peak-season opportunities are lost, and customers notice. Late replenishment drives cancellations, negative reviews, and lost repeat business.

These challenges are not rare glitches. They are why 55% of e-commerce brands still rely on manual or semi-manual inventory processes and why scaling without a real-time multichannel system is risky.

https://www.youtube.com/watch?v=gy3MQwbY22I

Key Components of Effective Multichannel Inventory Management

There is no single “magic button” that fixes inventory chaos overnight. High-performing multi-channel sellers rely on a system architecture built on multiple, tightly connected components. When even one of these pillars is weak, inventory errors multiply rapidly across channels.

Below are the six essential components that power reliable, scalable multi-channel inventory management.

1. Real-Time Inventory Sync Across Every Sales Channel

Real-time inventory sync is essential for multichannel selling. Every sale, return, or stock change updates right away. This applies to online stores, marketplaces, and physical POS locations.

Even small delays can cause stock errors. Customers may see items that are not available. Real-time sync fixes this. It shows accurate stock levels, prevents overselling, and keeps orders moving smoothly.

2. Centralized Inventory Visibility (Single Source of Truth)

As businesses sell on more channels, inventory data can get scattered. It may live in different dashboards or spreadsheets. This creates confusion.

Centralized inventory visibility brings all stock data into one system. Teams see accurate inventory levels in real time. This makes planning easier, speeds up fulfillment, and removes guesswork from daily operations.

3. Automation for Replenishment, Alerts, and Stock Control

Manual inventory tracking does not scale well. It becomes slow and error-prone as order volume grows. Automation solves this problem.

Automated systems track stock levels at all times. They send alerts before the stock runs low. They also help reorder inventory on time. This reduces errors and keeps inventory stable, even during busy sales periods.

4. Seamless Integrations Across the Commerce Ecosystem

Inventory accuracy depends on connected systems. E-commerce platforms, marketplaces, warehouses, POS systems, and fulfillment tools must work together.

Strong integrations keep data flowing without delays. Weak connections create data gaps and errors. When systems stay connected, inventory updates stay accurate across every sales channel.

5. Multi-Location and Warehouse-Level Inventory Control

Most growing businesses store inventory in more than one place. Stock may be in warehouses, retail stores, or fulfillment centers.

Advanced inventory systems track stock by location. They choose the best place to ship each order. This speeds up delivery, lowers shipping costs, and improves order accuracy.

6. Forecasting, Analytics, and Inventory Intelligence

Modern inventory management goes beyond tracking stock. It helps predict future demand. Forecasting tools use past and current sales data to guide decisions.

With clear analytics, businesses can plan ahead. They avoid overstocking and reduce shortages. Better forecasting turns inventory planning into a growth advantage instead of a risk.

Best Practices for Scaling Multichannel Inventory

Scaling multichannel inventory isn’t about adding more sales channels. It’s about growing without losing control. Many businesses scale fast but struggle with stock errors, delays, and unhappy customers because their inventory systems aren’t built for growth.

The most successful brands follow a few proven practices to keep inventory accurate, efficient, and scalable. These practices are as follows:

Centralize Inventory Visibility:

Maintain a single, unified view of inventory across all channels and locations. Centralized visibility ensures teams know exactly what stock is available, where it’s located, and how it’s moving, reducing oversells and stockouts while enabling smarter decisions.

Automate Inventory Updates:

Manual inventory tracking is a slow-burning problem. Each sale, return, or update adds risk. Automated multichannel inventory sync prevents mistakes before they happen. It updates stock in real-time across every channel, keeping your business running smoothly and customers satisfied.

Standardize SKUs and Naming:

Inconsistent SKUs and product names create confusion and overselling. A master SKU system ensures the software knows exactly what’s what across all platforms. Consistent identifiers reduce errors, speed up fulfillment, and make reporting accurate and reliable.

Prioritize Channel Liquidity:

Not all channels perform equally. Some convert faster and generate higher ROI. Smart inventory rules allocate stock to your most profitable channels first. This ensures your best-performing channels never run out while less critical channels wait.

Plan for Peak Seasons Early:

Holidays, Black Friday, and flash promotions can overwhelm unprepared systems. Real-time data and forecasting let you stock smarter and avoid overselling. Planning early ensures you capture every sale opportunity while keeping inventory under control.

Continuously Monitor KPIs:

Don’t wait until the quarter ends to find problems. Track stockouts, oversells, fulfillment accuracy, and carrying costs in real time. Monitoring KPIs continuously helps you fix issues early, reduce errors, and make smarter, faster inventory decisions.

With the right practices, inventory becomes a growth engine, not a risk. Automation, smart allocation, and real-time monitoring keep stock accurate and customers happy. Scaling across channels turns into efficiency, confidence, and more sales.

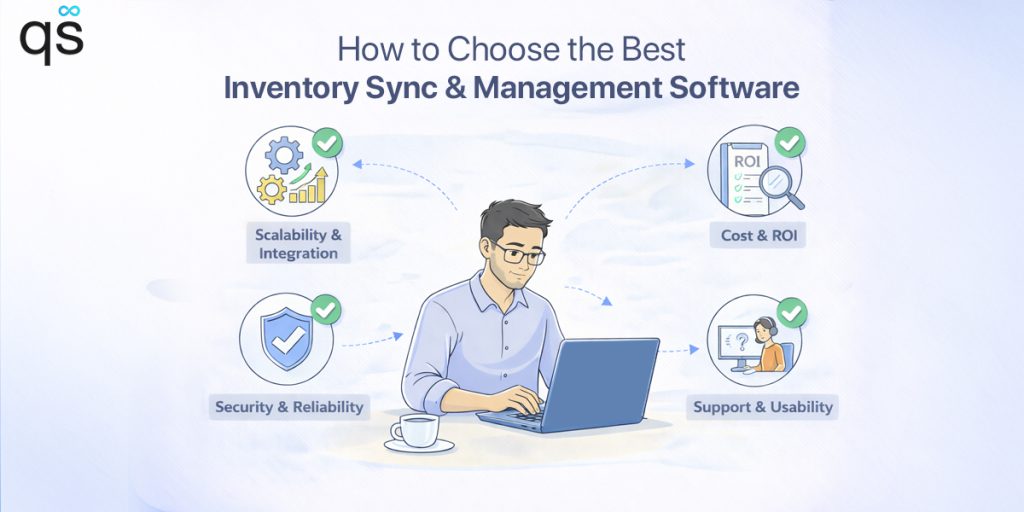

Choosing Multichannel Inventory Syncing Software For Multichannel Selling

Not all inventory software is built to support real growth. Many tools look powerful on the surface, but collapse once order volume increases, channels multiply, or fulfillment becomes complex.

Choosing the wrong system doesn’t just slow operations. It leaks revenue. The right inventory management software keeps stock accurate, teams aligned, and customers confident. Here’s what matters when deciding.

True Automation, Not Just Syncing:

Go beyond basic stock updates. Look for a system that automates multichannel inventory adjustments in real-time without manual uploads or scheduled batching. The best solutions automate low-stock alerts, generate purchase orders when thresholds hit, and send daily inventory reports without you lifting a finger. If it still requires spreadsheets to stay accurate, it won’t keep pace with your growth.

Deep Native Integrations:

Your software should integrate deeply, not superficially, with every platform you use: your ecommerce store, marketplaces, POS systems, fulfillment centers, and warehouses. Native connections eliminate the lag and breakage common with middleware. When inventory flows in real time across all channels, you prevent the overselling and stockouts that erode customer trust.

Real-Time Visibility from One Dashboard:

Delayed data leads to poor decisions. Choose a system that offers a single source of truth, showing inventory levels across every channel and location instantly. This unified view lets you route orders intelligently, respond to demand shifts immediately, and stop relying on guesswork during peak periods.

Smart Controls and Preventive Alerts:

Reactive inventory management costs money. Prioritize software with built-in rules for low-stock thresholds, automated reorder points, and configurable alerts that notify the right people before problems occur. This shifts your team from firefighting to strategic planning.

Scalability Without Performance Drops:

Growth means more SKUs, locations, orders, and data. Your platform should handle high-volume complexity without slowing down or requiring constant IT intervention. Test whether it maintains speed and accuracy as you scale. If it becomes a bottleneck, it’s not a growth tool.

Unified Operations Hub:

Ultimately, your inventory software should create a centralized command center for your business. It should simplify operations as complexity increases, reduce errors across channels, and give you control whether you’re managing five orders or five thousand. When chosen correctly, the system becomes invisible—it just works, keeping every channel aligned and every customer promise fulfilled.

Automation by Default, Not by Exception:

Every human touchpoint introduces lag, inconsistency, and error that multiplies across channels. A reliable inventory syncing solution automates multichannel updates by default. Stock changes should propagate instantly across every connected platform, without the need for spreadsheets or scheduled syncs.

When automation is done right, inventory accuracy becomes continuous rather than corrective. If your system still depends on manual intervention to stay accurate, it’s already falling behind the pace of growth.

Native Connectivity Across Sales Channels:

Inventory software should not “kind of” integrate. It must connect deeply and reliably with the platforms you sell on. This includes your ecommerce store, marketplaces, POS systems, fulfillment partners, and warehouses.

Native integrations ensure inventory flows in real time, without delays caused by fragile middleware or broken connectors. When systems don’t communicate seamlessly, inventory errors compound quickly, and customers feel it first.

Real-Time Visibility Without Lag:

Delayed inventory data is almost as bad as no data at all. Decisions made on outdated numbers lead to overselling, misallocated stock, and fulfillment chaos.

A strong system provides real-time inventory visibility across every channel and location from a single dashboard. This “single source of truth” allows teams to act with confidence, route orders intelligently, and respond instantly to demand changes.

Built-In Rules, Alerts, and Smart Controls:

The best inventory syncing solutions don’t wait for problems. It prevents them. The ability to define rules for low-stock thresholds, automated alerts, and reorder logic separates reactive businesses from resilient ones.

These controls allow teams to stay ahead of stockouts instead of scrambling after revenue is already lost. Automation backed by rules turns inventory management from firefighting into foresight.

Designed to Scale Without Breaking:

Growth comes with complexity, which means more SKUs, more locations, more orders, and more data. Your inventory system must handle this without slowing down or requiring constant maintenance.

The right platform supports high SKU volumes, multiple locations, and without performance drops. If your software struggles as you grow, it’s not a growth tool. It’s a bottleneck.

Growth Enabled, Not Create Risk:

Multi-channel inventory management software should simplify operations as complexity increases. It should reduce errors, protect revenue, and give your team control even during peak demand.

When chosen correctly, inventory software becomes invisible. It just works in the background, keeping every channel aligned and every order accurate. That’s when scaling stops feeling risky and starts feeling predictable.

Start your free 14-day trial and experience effortless multichannel inventory management.

Final Words: Reinvent Your Inventory With The Right Solution

In short, every unsynced SKU or delayed update isn’t just an error. It’s lost sales, angry customers, and wasted time. Spreadsheets and manual updates can’t keep up with multiple stores, marketplaces, and social channels.

The right syncing system fixes it all. Stock updates in real-time, oversells disappear, alerts happen automatically, and your team finally works without constant firefighting. With QuickSync, your multichannel inventory management gets effortless across every channel.

Ready to eliminate oversells, slash stockouts, and unlock unstoppable ecommerce growth? Sign up on QuickSync today and try it out for 14 days free trial.

FAQs

1. What is multichannel ecommerce inventory management software?

Multi-channel inventory management software helps you manage stock from one place. It connects all your sales channels. When a product sells, inventory updates right away. This helps avoid overselling and stock errors.

2. How does inventory management software help multichannel sellers?

It keeps inventory in sync across all platforms. This includes ecommerce stores, marketplaces, POS systems, and retail locations. Sellers can track stock easily. Orders ship faster. Inventory stays balanced everywhere.

3. What’s the difference between multichannel and omnichannel inventory management?

Multi-channel inventory management tracks stock across different sales channels. Omnichannel inventory management connects those channels into one experience. Both depend on real-time inventory updates and centralized control.

4. How does multi-channel inventory management prevent lost sales and overselling?

Lost sales happen when stock data is not updated. This system updates inventory as soon as an order is placed. That prevents overselling. It also reduces order cancellations and stock issues.

5. Can inventory management software track multiple warehouses and stores?

Yes. Inventory management software tracks stock across warehouses and stores. It also works with POS and warehouse systems. This gives clear visibility into inventory at every location.

6. How does inventory forecasting work in multi-channel inventory management?

Inventory forecasting uses past sales data. It looks at demand trends and sales speed. This helps predict future inventory needs. Businesses can avoid overstocking and reduce shortages.

7. Why is real-time inventory visibility important for customer experience?

Real-time visibility shows customers what is actually in stock. This prevents order problems. It also allows faster fulfillment. Customers get a smooth shopping experience online and in-store.

8. How does multi-channel inventory sync support business growth?

Inventory sync improves accuracy and control. It reduces manual errors and wasted time. Businesses can manage more sales channels with ease. This makes it easier to grow without added complexity.

Leave a Reply