The e-commerce sector is booming faster than ever. However, inventory mistakes still cost businesses massively. Inventory distortion back in 2023 (stockouts + overstock) cost retailers an estimated $1.77 trillion globally. That’s bigger than the GDP of many countries.

Based on personal experience, it often takes just one missed stock update. Sales are lost. Customers get frustrated. Brand trust takes a hit. That’s why automated inventory management is no longer a nice-to-have. It’s essential.

Automation keeps stock accurate in real-time, prevents overselling and stockouts, and protects revenue when demand surges.

Feeling overwhelmed by all of this? Don’t worry. This guide shows omni-channel sellers what inventory automation is, why it matters, and how real-time sync tools can turn inventory from a risk into a growth engine.

What Is Automated Inventory Management?

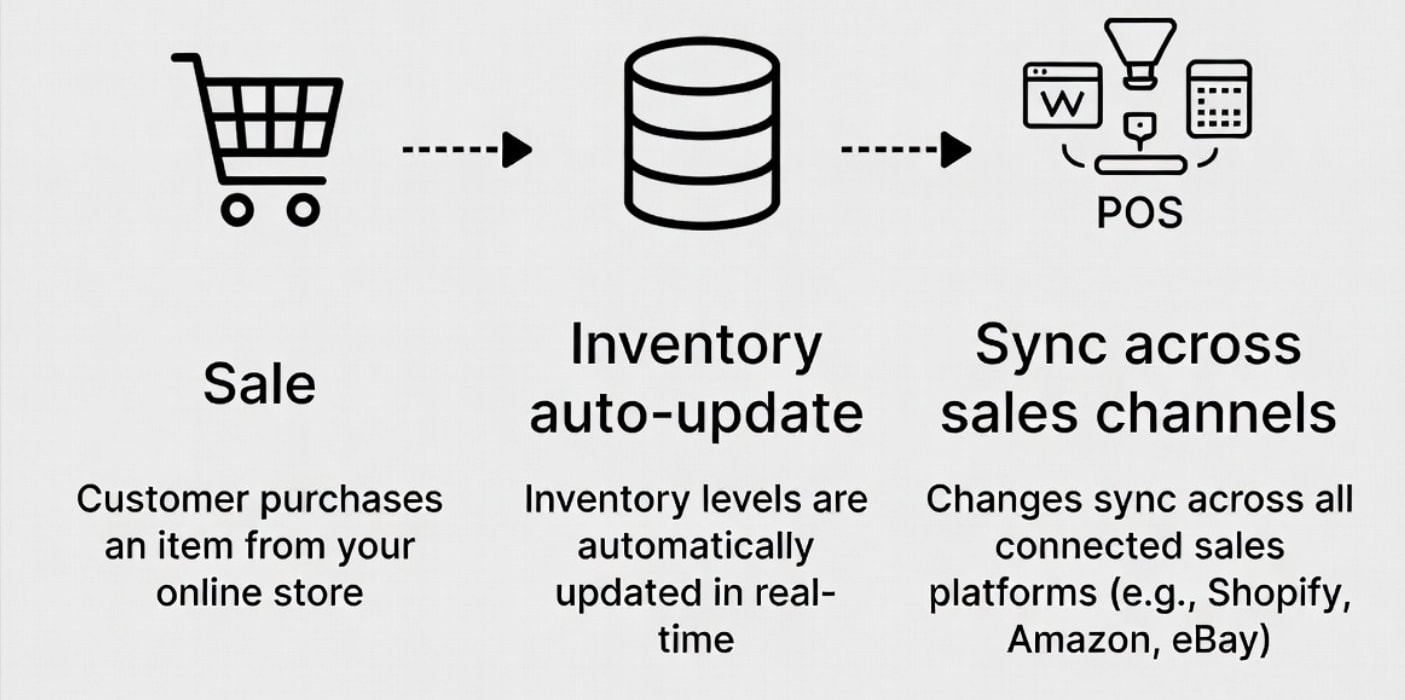

Automated inventory management is a smart way to track and control your products using software. Instead of counting items or updating stock manually, the system does it for you automatically whenever a sale happens.

For example, if you sell 10 notebooks online and one notebook is sold, the system instantly updates the stock to 9 in all your stores. No manual work needed.

Automated inventory systems connect all your multiple sales channels, online stores, marketplaces, physical shops, and warehouses. So stock updates happen in real-time.

Instead of using spreadsheets or multiple dashboards, automation manages everything for you. Saving time, reducing mistakes, and making inventory management easy and stress-free.

Why Automation in Inventory Management Matters for E-commerce Sellers

As e-commerce businesses grow, inventory becomes harder to manage. What helps for one online store often breaks when you add more sales channels, products, or fulfillment locations.

Industry research shows that inventory management mistakes like stockouts and overstocks cost retailers trillions worldwide each year. For e-commerce sellers, even small inventory errors can lead to cancelled orders, refunds, bad reviews, and lost customers.

Without ecommerce inventory automation, merchants frequently face:

- Manual inventory updates across platforms and marketplaces

- Delays between orders and stock adjustments

- Conflicting inventory data across systems

- Higher risk of overselling and fulfillment errors

This is why automated stock management is essential for modern e-commerce growth. Automation keeps inventory accurate as order volume increases, supports seamless multi-channel selling, and reduces costly human errors.

Difference Between Manual and Automated Inventory Management?

If you’re planning to grow beyond one sales channel, the difference between manual and automated inventory becomes impossible to ignore.

Business Impact | Manual Inventory Management | Automated Inventory Management |

Stock Accuracy | Frequently inaccurate due to human errors | Near-perfect accuracy with real-time system updates |

Overselling Risk | High with delayed updates cause double selling | Eliminated with real-time inventory locking |

Multi-Channel Selling | Hard to manage across platforms | Seamless syncing across all sales channels |

Order Fulfillment | Slower and error-prone | Faster, smoother, and more reliable |

Time Spent Managing Inventory | Hours spent daily on manual updates | Runs automatically in the background |

Customer Experience | Cancellations, delays, and frustration | Reliable delivery and higher customer trust |

Revenue Protection | Lost sales from errors and stock issues | Maximized sales with accurate availability |

Operational Stress | Constant firefighting and fixes | Predictable, stress-free operations |

Long-Term Cost | Hidden costs from refunds and mistakes | Lower total cost with higher efficiency |

Looking at the comparison table, the difference is clear. Inventory automation outperforms manual methods in accuracy, scalability, and revenue protection.

That’s why it’s essential for modern multi-channel sellers’ growth.

Common Inventory Problems Ecom Sellers Face Without Automation

Inventory issues don’t usually explode overnight. They creep in quietly as your business grows with more products, more orders, more sales channels. What once felt manageable suddenly turns into daily stress, constant fixes, and unhappy customers.

Without inventory automation, these problems don’t just slow you down, they actively hold your business back.

Overselling Across Channels:

Imagine selling the same product twice at the same time on two different platforms. One customer gets it. The other gets an apology. That’s overselling.

It happens when inventory isn’t synced in real-time, and the damage goes far beyond a single refund. Research shows that overselling can cost retailers up to $1 trillion annually in lost sales.

Canceled orders hurt customer trust, increase support tickets, and leave buyers with a bad impression they won’t forget.

Stockouts That Kill Sales:

A stockout happens when an item appears available but is actually out of stock, or when available products are hidden because the system hasn’t been updated. Manual updates can’t keep up with real-time sales.

The result?

Missed opportunities, abandoned carts, and shoppers heading straight to your competitors. Every stockout is a reminder that customers don’t wait; they move on.

Messy and Inaccurate SKU Data:

As your catalog grows, product data becomes harder to control. Variants don’t match. Bundles break. SKUs mean different things on different platforms.

Incorrect product data is one of the top reasons returns happen, and returns cost e-commerce businesses up to 20% of total revenue annually.

Without a single source of truth, inventory becomes guesswork. Wrong items get shipped. Returns pile up. And your team spends hours untangling mistakes that should never have happened in the first place.

Human Errors That Snowball Fast:

Human updates typing numbers into spreadsheets or dashboards are slow and prone to mistakes like typos, missed entries, or mismatched quantities.

A missed update here. A wrong quantity there. Suddenly, orders are wrong, fulfillment is delayed, and your team is scrambling. Manual processes don’t just slow growth. They make scaling risky.

Fulfillment Delays That Hurt Your Brand:

When inventory data is unclear, fulfillment suffers. Orders take longer to pick, pack, and ship. Delivery promises get missed. Customer expectations aren’t met.

And today, fast and accurate delivery isn’t a bonus, it’s expected. Delays lead to poor reviews, lower ratings, and fewer repeat customers.

These common issues are not rare but everyday problems for sellers trying to grow without automation. That’s why automated stock management isn’t just about efficiency. It’s about protecting your revenue, your reputation, and your sanity as your business scales.

How E-commerce Inventory Automation Works in Multi-channel Selling

After dealing with overselling, stockouts, messy data, and fulfillment chaos, the next question is simple:

How does automation fix all of this?

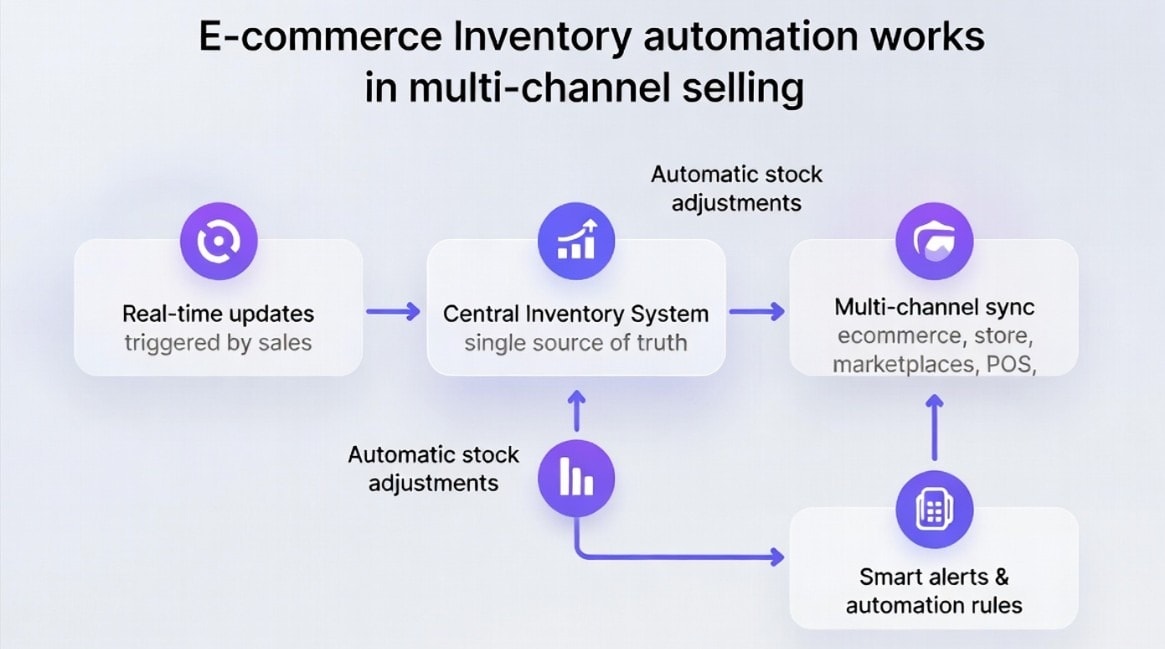

At its core, e-commerce Inventory Automation replaces manual guesswork with connected systems that talk to each other in real time. Instead of reacting to problems after they happen, automation keeps everything aligned behind the scenes quietly, consistently, and instantly.

Here’s how it works in practice.

One Central Source of Truth:

Everything starts with a single system that controls your inventory. This could be your e-commerce platform, an order management system, or a dedicated inventory tool.

No more different numbers on different platforms. No more debating which spreadsheet is “right.” One system holds the truth, and every other channel follows it.

Real-Time Inventory Updates:

The moment a customer places an order, inventory updates instantly. Whether the sale happens on your website, a marketplace, or a physical store, stock levels adjust in real time and sync everywhere else automatically.

There’s no waiting. No lag. No chance for two customers to buy the same last item.

Automatic Stock Adjustments Based on Orders:

As orders are placed, paid for, or fulfilled, inventory is deducted automatically based on your rules.

You decide when stock should move, and the system handles it without human input. That means fewer mistakes, cleaner data, and far less manual work for your team.

Seamless Multi-Channel Syncing:

Selling on multiple channels no longer means juggling multiple dashboards. Inventory quantities stay aligned across ecommerce stores, marketplaces, and POS systems without anyone lifting a finger.

Every channel always shows the same accurate stock numbers, no matter where the sale happens.

Smart Alerts and Automation Rules:

Automation doesn’t just track inventory, but also thinks ahead. Low-stock alerts, reorder triggers, and overselling prevention rules run quietly in the background. Instead of discovering problems too late, you’re warned early and can act before sales or customer trust are impacted.

Together, this workflow keeps inventory accurate even during high sales volume, flash sales, or peak shopping seasons. Automated inventory system gives you control, clarity, and confidence as your business scales.

Key Benefits of an Automated Inventory System for Multi-channel Sellers

Once inventory is automated, everything starts to feel lighter. Fewer fires to put out. Fewer “how did this happen?” moments. Instead of reacting to problems all day, your systems work quietly in the background to keep things running smoothly.

Here’s what changes when automation takes over.

Improved Inventory Accuracy:

When inventory is automated, the numbers you see are the numbers you actually have. Automated systems update stock instantly with each sale, return, or transfer, so you spend less time fixing mistakes and more time growing your business.

This accuracy matters. Businesses that automate inventory often see up to a 30% reduction in stock discrepancies, meaning fewer stockouts, oversells, and false “in-stock” listings that frustrate customers.

Massive Time Savings:

Manual inventory updates steal hours from your team every day. Think about all the spreadsheets, manual data entries, and system jumps. It adds up fast and takes focus away from real growth tasks.

With automation, those routine tasks happen on their own. Teams spend less time on busywork and more time on strategy, customer support, and expansion, fundamentally shifting the way your business works.

Fewer Overselling and Stockouts:

Automated systems sync stock across all selling channels in real time, so a product that’s sold on one channel is instantly reflected everywhere else. That means no more selling products you don’t actually have.

This real-time visibility can reduce stockouts by around 30%, keeping more sales on the table and fewer customers disappointed due to inventory errors.

Smarter Forecasting and Replenishment:

Clean, accurate data is the foundation of smart planning. When inventory data is automated, you can spot true demand patterns, seasonal shifts, and fast-moving products with much more confidence.

That makes forecasting easier and smarter, helping you order the right quantities at the right time and avoid costly excess stock or last-minute rush orders.

Better Customer Experience:

Customers want what they ordered, and they want it fast. When inventory is accurate and fulfillment is seamless, delivery times improve, cancellations drop, and trust builds.

Accurate stock data means customers see the right availability before they buy, leading to fewer surprises, better reviews, and stronger loyalty over time.

Scale Without Chaos:

As your brand grows, with more products, more locations, and more channels, manual inventory processes struggle to keep up. The complexity increases faster than your team can handle.

Automation takes on that complexity for you. It scales automatically with your business, meaning growth doesn’t come with extra stress or extra manual work. You get consistency and control even during the busiest seasons.

Key Challenges With Automating Inventory in E-commerce

While Software-driven inventory management delivers clear efficiency gains, it’s not something e-commerce businesses can turn on and forget. Without the right preparation and tools, automation can introduce new operational challenges instead of solving existing ones.

Understanding these challenges of multichannel selling upfront helps brands implement automation successfully and avoid costly mistakes.

Integration Complexity Across Multiple Systems:

Most e-commerce businesses sell across multiple platforms like online stores, marketplaces, POS systems, and more. Connecting all of them into one automated inventory system takes careful setup and accurate product mapping.

Each platform follows different inventory rules and data structures. Without clean integrations, inventory updates can fail, products can duplicate, and stock numbers quickly become unreliable.

Data Quality and Catalog Consistency Issues:

Inventory automation depends on clean, consistent product data. If SKUs, variants, or product details differ across platforms, automation can create errors instead of fixing them.

Duplicate SKUs, mismatched variants, missing attributes, and outdated records all lead to inaccurate stock syncing. Cleaning and standardizing your catalog is essential before automating inventory.

Multi-Channel Sync Conflicts:

Each sales channel manages inventory differently. Some update stock in real time, while others rely on delayed or batch updates. Return and cancellation rules also vary by platform.

These differences can cause issues such as:

- Delayed inventory updates on certain channels

- Stock levels that don’t reflect actual availability

- Orders appearing out of sequence or mismatched

A strong automation strategy accounts for these platform-specific behaviors to ensure accurate inventory across all channels.

Choosing the Right Inventory Automation Tool:

Not all inventory tools can handle the complexity of modern e-commerce. Some only support basic syncing, lack real-time updates, or struggle with high order volumes.

The wrong tool can lead to delayed updates, limited integrations, poor variant handling, and inflexible workflows.

The key isn’t avoiding automation, it’s doing it right. With clean data, realistic expectations, and the right tools, an automated inventory system becomes a reliable foundation for scalable e-commerce growth.

Essential Inventory Metrics E-commerce Brands Should Track

Automated inventory works best when guided by the right metrics. Real-time tracking helps brands make smarter purchasing decisions and prevent costly stockouts. Without these insights, even advanced automation can fall short.

Inventory Turnover Rate:

Inventory turnover measures how often stock is sold and replaced within a specific period. A healthy turnover rate indicates strong demand and efficient inventory planning, while a low turnover rate can signal overstocking, slow-moving products, or poor demand forecasting. Monitoring this metric helps brands strike a balance between cash flow and storage costs.

Sell-Through Rate:

The sell-through rate shows the percentage of inventory sold compared to the amount received during a given timeframe. This metric is especially important for seasonal products, promotions, and new product launches.

High sell-through rates indicate accurate demand planning, while low rates highlight excess inventory that may require markdowns or promotions.

Real-Time Stock Levels:

Knowing exactly how much inventory is available at any moment is critical for preventing overselling and stockouts. Real-time stock level tracking provides visibility across all warehouses, stores, and online sales channels, ensuring customers see accurate availability and operations teams can respond quickly to changes in demand.

Safety Stock Levels:

Safety stock represents the buffer inventory held to protect against unexpected demand spikes, supplier delays, or fulfillment issues. Tracking safety stock ensures businesses maintain service levels without tying up unnecessary capital in excess inventory.

Automated inventory management software can dynamically adjust safety stock based on sales trends and lead times.

Inventory Shrinkage:

Shrinkage refers to inventory losses caused by theft, damage, miscounts, or system discrepancies. Left unchecked, shrinkage can quietly erode profits and distort inventory data.

Automated inventory management systems help identify shrinkage faster by comparing expected stock levels against actual counts in real time.

Reorder Points and Replenishment Triggers:

Reorder points define the exact moment inventory should be replenished to avoid stockouts. When paired with automation, reorder points trigger alerts or automatic purchase orders based on real-time sales velocity, lead times, and safety stock thresholds. This ensures consistent availability without manual monitoring.

Smart inventory management systems make these metrics easier to track because data stays consistent across channels.

The Key Systems That Make Inventory Automation Work For Omnichannel Sellers

An effective automated inventory system isn’t driven by a single system. It depends on multiple tools working together in a connected ecosystem. Each tool plays a specific role in keeping inventory data accurate, synchronized, and actionable across the entire operation.

Inventory Management Software:

Inventory software tracks stock, SKUs, and product details in one place. It shows available, reserved, and incoming inventory in real-time. By centralizing data, businesses reduce errors and eliminate spreadsheets. This helps teams make smarter purchasing decisions.

Order Management Systems (OMS):

An OMS manages orders across all sales channels. It assigns inventory based on availability, fulfillment rules, and delivery locations. This prevents overselling, keeps orders accurate, and creates a smoother customer experience from checkout to delivery.

Warehouse Management Systems (WMS):

A WMS streamlines warehouse tasks like receiving, picking, packing, and shipping. It tracks inventory movement in real time and guides staff through efficient workflows. This keeps warehouse stock counts accurate and reduces fulfillment errors.

APIs and Integrations:

APIs connect e-commerce stores, marketplaces, POS systems, and inventory tools. They allow real-time data exchange for sales, returns, and adjustments. Strong integrations keep inventory synced across platforms and remove manual work.

Automation Platforms:

Automation platforms sync inventory across stores, marketplaces, and POS systems. They handle complex multi-channel updates in real-time. This prevents stock discrepancies, reduces manual work, and supports scalable growth for e-commerce businesses.

For businesses selling across multiple channels, multichannel automation solutions that focus on real-time inventory syncing play a critical role in maintaining accuracy, reducing operational friction, and supporting sustainable growth.

How Real-Time Inventory Sync Supports Automation

One of the biggest gaps in inventory automation is real-time synchronization across channels. This is where tools like QuickSync add real operational value.

QuickSync supports an automated inventory system by:

- Syncing inventory instantly across ecommerce stores, marketplaces, and POS systems

- Updating stock automatically when orders are placed or fulfilled

- Preventing overselling by locking inventory across channels in real time

- Reducing manual reconciliation between platforms

Instead of managing inventory separately on Shopify, Amazon, Etsy, or retail systems, QuickSync keeps stock aligned automatically.

For merchants operating in multi-channel or omni-channel environments, real-time inventory updates are the backbone of reliable automation.

Best Practices for Implementing Inventory Automation

Automated inventory works best when used with structure and intention. E-commerce and omnichannel sellers that follow proven best practices avoid common pitfalls. This ensures automation improves accuracy instead of causing new problems.

Standardize SKUs Across All Sales Channels:

Consistent SKU naming is the foundation of inventory automation. Every product and variant should use the same SKU across ecommerce stores, marketplaces, POS systems, and warehouses.

When SKUs are standardized, automation tools can match products correctly and sync inventory without conflicts or duplication.

Clean and Align Product Data Before Automating:

Automation magnifies existing data issues. Before enabling automated inventory workflows, brands should clean their catalogs by removing duplicate listings, fixing mismatched product details, and aligning variants correctly.

A clean product database ensures smoother syncing and fewer errors once automation is live.

Prioritize Real-Time Inventory Syncing:

Inventory automation only works when updates happen instantly. Delayed or scheduled syncing increases the risk of overselling, stock discrepancies, and customer dissatisfaction.

Real-time inventory syncing ensures that every sale, return, or adjustment is reflected immediately across all connected platforms.

Define Clear Automation Rules and Logic:

Successful automation requires clear rules. Brands should decide how inventory is deducted after a sale, how stock is reserved during checkout, and how replenishment is triggered.

Clear automation logic keeps inventory movement predictable and prevents conflicting updates between systems.

Enable Alerts, Thresholds, and Reorder Points:

Automated alerts play a critical role in proactive inventory management. Low-stock notifications, safety stock thresholds, and automated reorder points help businesses respond before shortages occur.

These controls prevent last-minute surprises and support consistent stock availability.

Monitor Performance and Optimize Continuously:

Regular monitoring helps identify sync issues, adjust thresholds, and refine workflows as the business grows. Continuous optimization ensures inventory automation evolves alongside changing sales patterns and operational needs.

If the above-mentioned practices are implemented correctly, inventory automation strengthens operations, improves accuracy, and supports scalable growth without adding complexity or confusion.

Final Words

Mulit-channel ecommerce sector moves fast, and manual inventory can’t keep up. Automation changes the game. It gives you real-time stock accuracy, prevents costly mistakes, and keeps orders flowing smoothly everywhere you sell.

With tools like QuickSync, your inventory becomes a growth engine, not a headache.

If you want to scale, stay ahead, and run your business with confidence, automated inventory management isn’t optional. It’s essential.