Ever had to cancel an order because the product was out of stock? That’s overselling – and it quietly eats into your revenue, reputation, and customer trust. Overselling does not look like a big problem at first. One order gets cancelled, a refund is issued, and you move on. But when this happens repeatedly, it quietly damages your business.

According to the IHL Group, retailers lose over $1.7 trillion each year due to inventory errors like overselling and stockouts. In most cases, overselling happens because inventory data is inaccurate or the inventory sync gets delayed.

In this guide, I will explain why overselling happens, how it affects your business, and most importantly, how to prevent overselling using the right processes and tools.

Why Overselling Happens in eCommerce

In simple terms, overselling happens when you have more orders than the inventory. Due to overselling, you face a loss despite having a high bandwidth of customers and a good sales season. Before diving into the details of how to prevent overselling. Let’s first understand why overselling happens.

Inaccurate Inventory Data

Inaccurate inventory data is the most common reason overselling occurs. Inventory records may show products available, even when you don’t have one. You continue to sell products for which you don’t have sufficient stock in your warehouse. This mismatch usually comes from delayed inventory updates or manual tracking.

When inventory management relies on spreadsheets or outdated systems, errors are common. Retailers often find out the issue only after customers have already paid. At that point, the damage is already done.

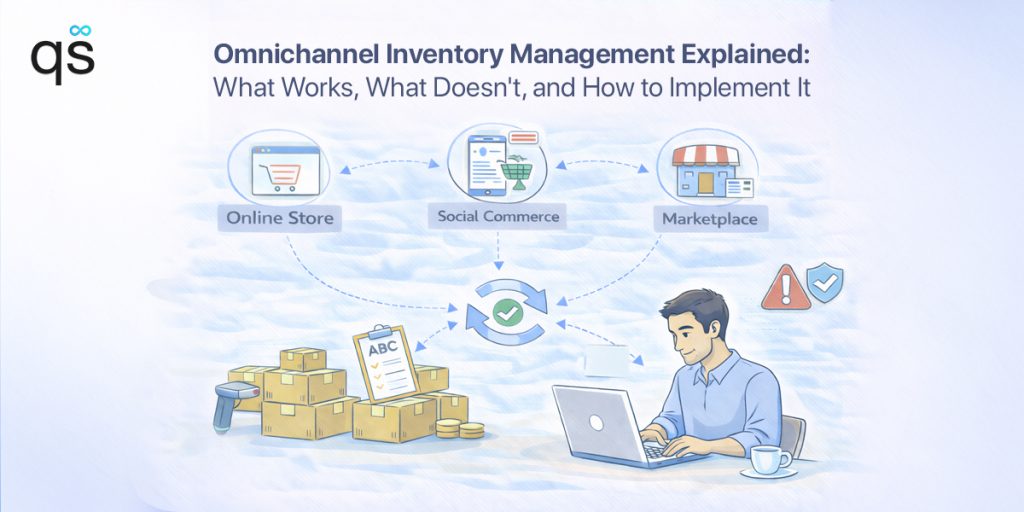

Selling the Same Product Across Multiple Sales Channels

Most retailers today sell on more than one sales channel. Some retailers are selling on their own website, marketplace, POS systems, and TikTok shop. Each sales channel processes orders separately, and inventory is handled separately.

If inventory does not sync across all channels, one sale does not reduce stock everywhere. The same product keeps selling on other platforms. This is how overselling starts without anyone noticing immediately.

High Demand and High Traffic Periods

Overselling commonly occurs during high-demand sales seasons. Flash sales, promotions, and seasonal events bring sudden traffic spikes. Inventory systems that usually break during these order surge seasons.

When hundreds of shoppers try to purchase at the same time, even a small delay in stock updates causes overselling. The unpredictable nature of demand makes manual control impossible.

Manual Updates by Multiple Users

When multiple users manage inventory manually, errors increase. One team member updates stock on the website, while another forgets to update a marketplace listing. These small gaps lead to big inventory management problems.

As businesses grow, relying on people instead of systems becomes risky. Manual inventory control does not scale well.

Disconnected Online and Offline Systems

Retailers running physical stores and ecommerce sites often use separate systems. POS sales may not reflect the stock on the online store immediately. This creates an inventory mismatch between the physical and online stores.

A customer may buy the last unit in-store, while another customer purchases the same item online. Without real-time syncing, overselling becomes unavoidable.

Poor Variant and SKU Management

Variants like size, colour, or style usually come in the same product listing. If SKUs are not mapped correctly, inventory gets deducted from the wrong variant. This leads to selling unavailable options even when the total stock exists.

Customers often order a variant that appears available but cannot be fulfilled. Over time, this creates frequent cancellations and inventory confusion across channels.

Supplier Delays and Reliability Issues

Suppliers play a key role in inventory planning. When production or shipping is delayed, stock runs out faster than expected. Even a small delay can break your restocking plan.

Retailers may continue selling products, assuming new stock is on the way. When shipments arrive late, this leads to stockouts, order cancellations, and unhappy customers. Without backup suppliers or safety stock, overselling becomes hard to avoid.

Lack of Safety Stock

Safety stock acts as a backup when demand rises or deliveries slow down. Without this buffer, inventory runs out faster than planned. Retailers continue selling, assuming stock is still available.

When delays or sudden product demand hit, there is no inventory to cover the gap. This leads to overselling, cancelled orders, and lost customer trust.

Most overselling issues are not caused by demand, but by outdated systems that fail to update inventory fast enough.

Impact of Overselling on E-commerce Businesses

Overselling not only results in the cancellation of orders. It directly impacts revenue, operations, and brand value. In fact, almost 40% of retailers cancel at least one in ten orders because inventory data isn’t accurate, often due to overselling and stock mismatches, as per eCommercenews.

Retailers who immediately take action to prevent overselling issues enjoy higher profit numbers. Here are some of the common problems that retailers face due to overselling products.

Loss of Customer Trust

When you sell products more than you have in stock, you end up cancelling orders. In result, you end up losing customer trust in your store. One bad experience is enough to keep a customer from returning to your store again.

When buyers pay for a product and later hear it is out of stock, they feel misled. Even if refunds are issued quickly, the experience feels disappointing. Over time, repeated overselling reduces customer loyalty and repeat purchases.

Damage to Brand Reputation

Overselling damages brand reputation. Customers share negative experiences through reviews, social media, and word of mouth. These bad reviews spread on social media and damage your brand value.

For US and UK retailers operating in competitive markets, reputation matters. One bad experience can push buyers toward competitors.

Increased Refunds and Financial Losses

Every time you cancel an order, you are forced to process a refund. This creates a direct revenue leak in your financial records. You also lose money on shipping, listing fees, and payment processing costs.

Over time, these small losses add up and impact overall profitability. Overselling means spending more money to fix mistakes instead of growing the business.

Operational Stress Across Teams

Overselling creates pressure across departments. Customer support handles high volume of complaints. Warehouse teams search for stock that does not exist. Finance teams deal with mismatched inventory records.

This stress reduces productivity and increases internal frustration. Teams spend more time fixing mistakes than focusing on growth. Over time, this leads to burnout and operational inefficiency.

Slower and Riskier Business Growth

Growth becomes difficult when inventory is unreliable. Adding new sales channels or warehouses increases complexity. Without proper inventory systems, scaling leads to more errors instead of more revenue.

Operations become harder to manage as order volume increases. Teams lose visibility into stock levels across channels. This slows expansion and limits long-term business success.

Best Practices to Prevent Overselling

The good news is that overselling is an complety manageable issue. Retailers can take some steps and use tools to prevent overselling of products. If you are someone who is struggling with overselling, these tips and insights will help you sell smoothly.

Maintain Accurate Inventory Records

According to retail operations reports, nearly 60% of inventory errors happen due to delayed stock updates across channels. If you fix inventory inaccuracies, you have solved 90% of the overselling problem. Inventory records must always match physical inventory. This includes stock in warehouses, retail stores, and fulfillment centers. Regular audits help identify mismatches early.

Use Real-Time Inventory Updates

Your inventory should update in real-time after every sale, return or exchange is made. If you are selling on multiple sales channels, and people are buying the same product simultaneously. Your inventory management system should update the stock in real-time accordingly. Delayed updates create gaps and lead to inaccurate inventory numbers. Real-time inventory syncing removes those gaps.

Set Reorder Points Using Historical Data

Historical data shows how products were sold in the past. It helps retailers see which items sell fast and when demand increases. Reorder points set a clear level that tells you when to restock. This ensures new stock arrives before the product runs out. As a result, customers do not order products that are no longer available.

Centralized Inventory Management

Inventory should be managed from one central system, especially if you are selling on multiple channels like Shopify, Etsy, Clover, Amazon, etc. Centralized inventory management gives retailers a clear overview of their inventory across sales channels. It also reduces confusion and customer complaints.

Limit Sales When Stock Is Low

Some retailers keep buffer stock to avoid last-minute overselling. This means holding back a small quantity from being sold online. It provides a safety margin and helps in avoiding overselling. This practice is especially useful during high-traffic sales events and promotions. It also gives teams time to restock without cancelling orders.

Top Tools & Technology That Help Prevent Overselling

Retailers today have options to use tools that will help prevent overselling from scratch. As businesses grow and merchants sell across multiple channels, manual inventory control becomes unreliable.

Companies using real-time inventory tracking see inventory accuracy improve by up to 35–98%, which directly reduces overselling risks as per Wifitalents. Below are the most effective tools and technologies used by growing retailers.

Real-Time Inventory Sync Tools

Real-time inventory sync tools update stock levels instantly across all connected sales channels. When a product sells on one platform, inventory is updated everywhere in real time. This prevents overselling during high traffic periods, flash sales, and promotions. For multichannel retailers, a real-time sync tool like QuickSyncis essential to prevent overselling.

Inventory Management Systems (IMS)

An inventory management system helps retailers track stock, manage reorder levels, and monitor inventory movement. It provides bettervisibility into available, reserved, and incoming stock. While it may not sync multiple sales channels instantly on its own, it supports better planning and control.

Multi-Location Inventory Control Software

For businesses operating multiple warehouses or stores, location-based inventory control is critical. There are inventory sync tools like QuickSync that track stock separately at each location. This ensures orders are fulfilled from the correct warehouse and avoids false inventory availability across locations.

Demand Forecasting & Inventory Planning Tools

Demand forecasting tools analyze historical sales data to predict future demand. They help retailers plan inventory before high-traffic events. When used alongside inventory sync software, forecasting tools reduce overselling risks further. This combination is commonly used by mid-size and big retailers.

Automated Stock Alerts & Low-Stock Rules

Automated alerts notify retailers when stock reaches a critical level. Some tools can pause new listings or limit sales automatically when inventory is low. This adds a safety buffer and helps prevent last-minute overselling.

Channel Integration & Automation Tools

Channel integration tools connect platforms like Shopify, Amazon, Etsy, POS systems, and marketplaces. They eliminate manual updates and duplicate work. Automation ensures inventory data stays consistent across all channels at all times.

Why QuickSync Is the Best Tool to Prevent Overselling

Many growing retailers move to QuickSync after dealing with repeated order cancellations and inventory mismatches. QuickSync is built for multichannel sellers who want clear inventory visibility and fewer stock errors across ecommerce stores, marketplaces, POS systems, and retail locations.

QuickSync focuses on fixing the core causes of overselling. It keeps inventory updated in real time, reduces manual work, and supports businesses as order volume and product count grow.

Key features include:

- Real-time inventory sync across all sales channels, so every sale updates stock instantly

- Automatic SKU assignment to prevent mismatches caused by missing or incorrect SKUs

- Multi-warehouse inventory sync with accurate stock tracking per location

- POS, marketplace, and website integration to keep offline and online inventory aligned

- Built for high demand, large catalogues, and multiple users

- Easy setup with no technical knowledge required

- Affordable plans starting at $19, with no hidden costs

- 24×7 customer support to assist during peak sales and critical hours

Conclusion

Overselling is not a small mistake. It is a business risk that affects your profitability. Learning how to prevent overselling protects customer trust, revenue, and brand reputation. Manual processes are no longer enough for modern e-commerce. Therefore, inventory sync tools like QuickSync are essential to avoid overselling.

QuickSync provides real-time inventory sync, automatic SKU assignment, and multi-location support across all sales channels. It removes all the manual work, and you never oversell.

If you want to avoid overselling and scale with confidence, QuickSync is built to support that growth.

Get started with QuickSync’s 14-day free trial today and say goodbye to overselling issues.

FAQs

How to avoid overselling?

To avoid overselling, retailers need real-time inventory management across all sales channels. Inventory sync software updates stock after every sale. This keeps quantities accurate everywhere and prevents customers from ordering items that are no longer available.

How not to oversell?

Overselling happens when stock levels are not updated on time. It is caused by delayed updates and disconnected systems. Using multichannel inventory sync keeps stock levels aligned across websites, marketplaces, and POS systems, reducing errors and missed updates.

How to deal with overstocking?

To manage overstocking, retailers should track sales data and inventory in real time. Adjust reorder levels based on demand. Discount or bundle slow-moving products. Inventory sync software helps balance stock across online and offline sales channels.

What are the causes of overstocking?

Overstocking is caused by poor demand forecasting and inaccurate inventory data. Buying in bulk without sales insights adds risk. Disconnected inventory systems reduce visibility, leading to excess stock that increases storage costs and blocks working capital.

Can POS cause overselling?

Yes, POS systems can cause overselling when in-store sales do not sync instantly with online stock. A product may sell offline but still show as available online. Real-time POS inventory sync prevents this and keeps stock accurate everywhere.

What is the meaning of safety stock recommendations?

Safety stock recommendations mean keeping extra inventory for sudden demand or supply delays. This buffer helps prevent stockouts and overselling during sales spikes. When combined with real-time inventory tracking, it improves accuracy and protects order fulfillment.

What are the tools to prevent overselling?

Tools to prevent overselling include inventory sync software like QuickSync, real-time inventory management systems, and multichannel sync tools. These tools update stock instantly across ecommerce stores, marketplaces, and POS systems to keep inventory accurate.

What is the impact of variants and SKUs?

Poor SKU and variant management leads to inventory errors. Stock may deduct from the wrong size or colour. This causes overselling of specific variants, even when inventory exists, reducing accuracy and creating customer complaints.